If you’ve ever delved into the inner workings of your car’s engine, you may have come across the term “Reluctor wheel.” This seemingly simple component is actually essential to keeping your engine operating smoothly and efficiently. Let’s explore what a retraction wheel is, why it’s important, and how it functions.

What is a Reluctor Wheel?

Certain components play pivotal roles in vehicle functionality and efficiency in automotive engineering. One such component is the relay wheel, a crucial element within various systems, including ignition, ABS, and transmission. Understanding the intricacies of relay wheels is fundamental for comprehending their significance in modern automotive technology.

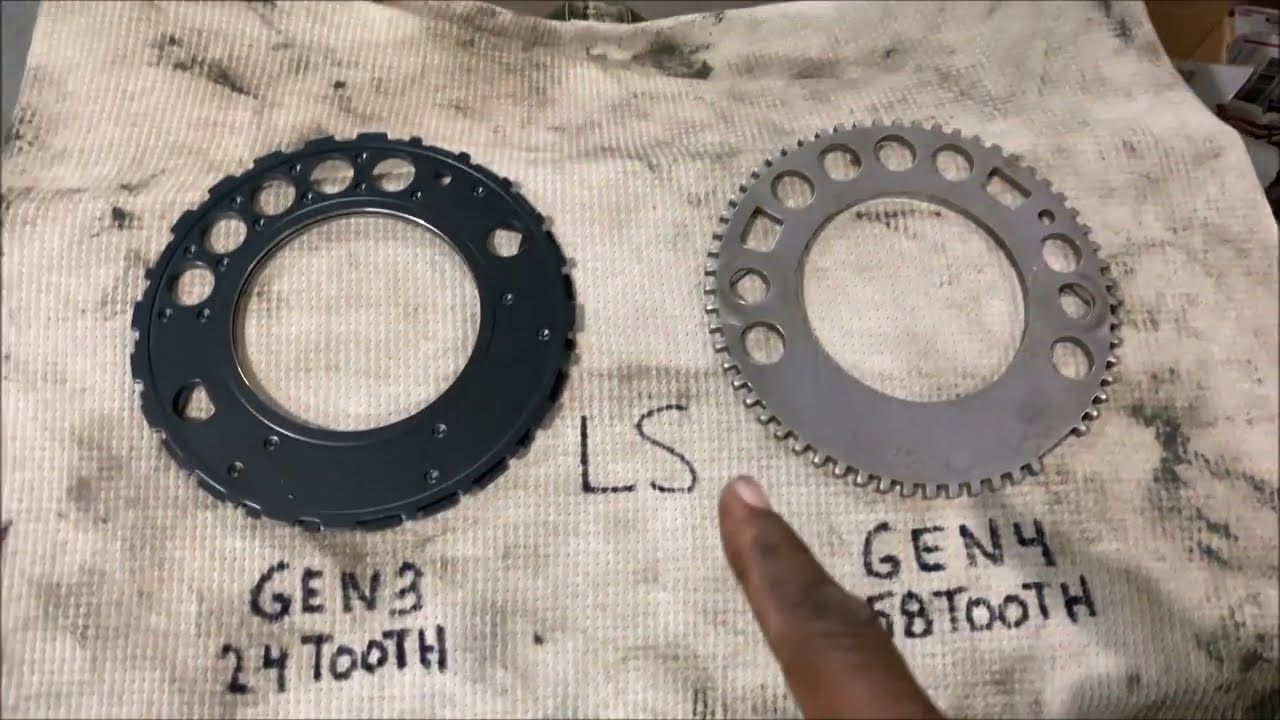

Focus on the Visual

- Definition: A Reluctor wheel (also known as a tone ring or timing wheel) is a toothed metal ring that’s typically press-fit onto the crankshaft of your engine. Its teeth have a specific pattern and spacing.

- Purpose: The Reluctor wheel works in conjunction with a crankshaft position sensor (CKP sensor). This magnetic sensor keeps track of the crankshaft’s position and speed of rotation.

- How it Works:

- As the crankshaft rotates, the teeth of the Reluctor wheel pass by the magnetic sensor.

- The presence and absence of these teeth create changes in the magnetic field.

- The sensor translates these fluctuations into an electrical signal.

- The engine control module (ECM) receives this signal and uses it to determine the crankshaft’s exact position.

Why is a Reluctor Wheel Important?

A Reluctor wheel is important because it serves as a critical component in various automotive systems. It provides essential input for sensors, enabling accurate measurements and control. Reluctor wheels are particularly crucial in ignition timing, ABS (Anti-lock Braking System), and determining the position of rotating components within the vehicle. Their precision and reliability contribute significantly to the overall performance and safety of vehicles, making them indispensable in modern automotive engineering.

The crankshaft position data relayed to the ECM is absolutely crucial for several engine functions:

- Ignition Timing: The ECM uses this data to precisely determine when to fire the spark plugs, ensuring optimal combustion.

- Fuel Injection Timing: The ECM needs this information to inject fuel into the cylinders at the perfect moment for the most efficient burn.

- Valve Timing: In modern engines with variable valve timing, the crankshaft position influences when the intake and exhaust valves open and close.

Types of Reluctor Wheels

There are two main types of relay wheels commonly found in engines:

- 24-tooth: An older design often found in earlier engine management systems.

- 58-tooth: A more modern design that offers greater precision and accuracy due to the increased number of teeth.

Signs of a Failing Reluctor Wheel

When a Reluctor wheel starts to fail, you might experience:

- Check Engine Light: The ECM may detect a fault with the CKP sensor or incorrect crankshaft position readings.

- Hard Starting or No-Start Condition: Without a precise crankshaft position, the engine may not start at all.

- Engine Misfires: Incorrect timing can lead to misfires.

- Rough Running: The engine may run erratically due to poor timing.

Advantages of Reluctor Wheels

Precision and Accuracy

Reluctor wheels provide highly precise and accurate measurements, making them indispensable in applications where reliability is paramount, such as engine management systems and transmission control.

Durability and Reliability

Reluctance wheels are made of strong materials and are engineered to endure difficult working environments. As a result, they provide remarkable longevity and dependability and guarantee steady performance for long periods.

Challenges and Limitations On Reluctor Wheel

Reluctor wheels encounter various challenges and limitations, impacting their performance and longevity in automotive systems. Heat generation poses a significant hurdle, as their proximity to the engine subjects them to high temperatures, leading to thermal distortion and inaccuracies. Corrosion is another concern, particularly in environments with moisture or corrosive substances that compromise the integrity of the wheel’s teeth. Mechanical stress during acceleration and deceleration accelerates wear and tear, affecting reliability.

Furthermore, size constraints and compatibility issues with sensors add complexity. Overcoming these hurdles requires innovative design solutions and advanced materials to enhance durability and accuracy, ensuring optimal performance in automotive systems.

Future Trends in Reluctor Wheel Technology

Innovations in Reluctor wheel technology are driving future advancements in automotive engineering. Researchers are exploring novel materials like carbon nanotubes and graphene, known for their exceptional strength and conductivity, to enhance reliability and performance. Complex designs may be made with additive manufacturing processes, which can reduce production costs and improve sensing accuracy.

Predictive maintenance and intelligent vehicle systems are made possible by the integration of cutting-edge sensor technologies, such as magnetostrictive and Hall effect sensors, which allow for real-time data collecting and processing. Reluctance wheels are expected to play an even more significant role in the next wave of automotive technology, which will guarantee safer, more effective, and autonomous cars as these trends continue to develop.

Conclusion

While it may look like a simple piece of metal, the relay wheel is an unsung hero in your engine’s symphony of operations. It silently ensures that the intricate dance of fuel, air, and spark happens at the exact right time. If you suspect your Reluctor wheel has reached the end of its life, consult with a qualified mechanic to ensure your engine stays in perfect condition.

FAQ

Are Reluctor Wheels only used in Automotive Applications?

While relay wheels are prominently used in the automotive industry, they also find applications in other fields, such as aerospace, industrial automation, and robotics.

What is a Reluctor in Automotive?

A Reluctor wheel is a component found in electronic ignition systems. It resembles a gear and is typically located near the top of the distributor shaft. The number of teeth on the relay wheel corresponds to the number of cylinders in the engine. As each tooth passes by a pickup coil, it decreases resistance to magnetic flux and enhances the strength of the magnetic field. This alteration triggers the electronic control unit, initiating the ignition process.

What is the Air Gap Between the Reluctor Sensors?

Reluctor sensors are highly sensitive to the gap between the sensor and trigger material. This gap needs precise adjustment to match consistently across each tooth. Unlike Hall effect sensors, Reluctor sensors demand a much tighter gap, usually around 10 thousandths of an inch or 0.25 millimeters, sometimes even less.

What are Some Common issues Associated with Reluctor Wheels?

Common issues include signal interference, sensor calibration discrepancies, and mechanical wear over time.

How do relay Wheels Contribute to Vehicle Safety?

Reluctor wheels provide crucial input for systems like ABS (Anti-lock Braking System), enabling precise monitoring of wheel speed and enhancing vehicle stability during braking.