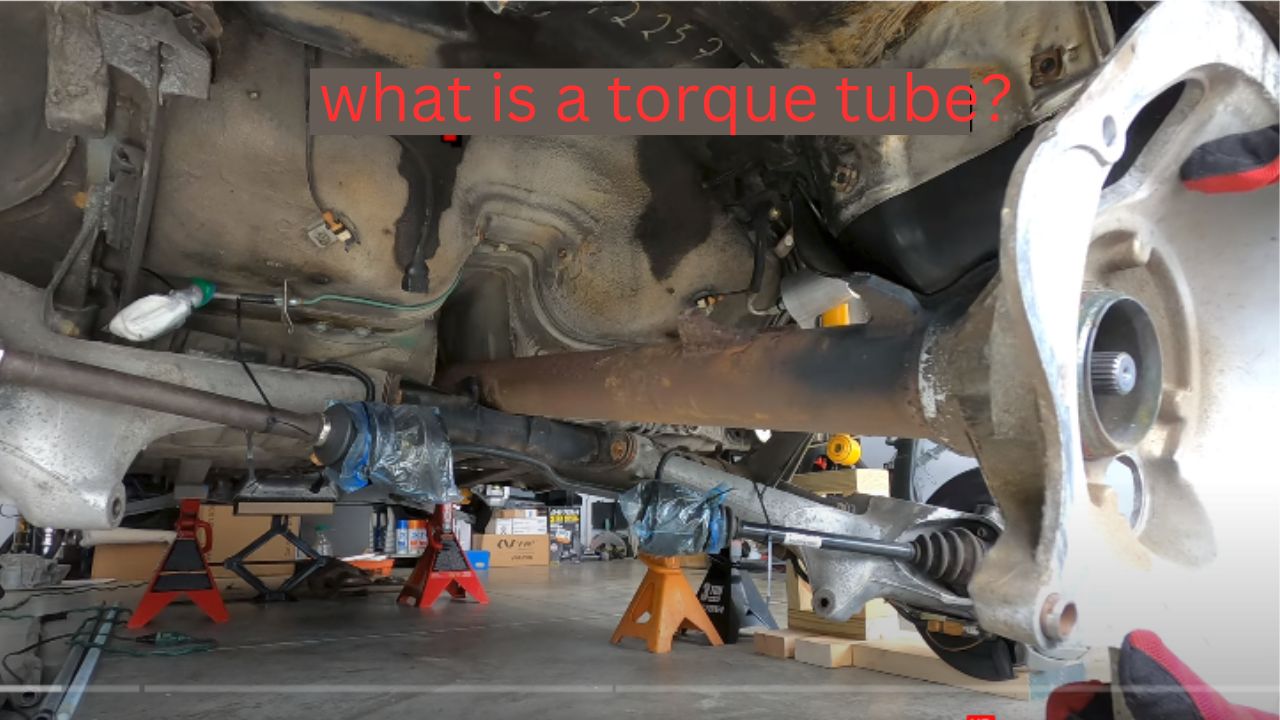

A torque tube is a vehicle’s drivetrain system component that transmits rotational force from the engine to the wheels. It consists of a hollow metal tube enclosing a driveshaft, which connects the transmission to the differential or axle assembly. The torque tube provides structural support and alignment for the driveshaft, ensuring efficient power transfer and minimizing drivetrain vibrations. This design helps maintain stability and control, particularly in high-performance or heavy-duty vehicles, enhancing overall driving performance and reliability.

How does a Torque Tube Work?

A torque tube transmits the rotational force the wheels generate to the car’s frame, ensuring optimal traction and stability. As the wheels exert torque in a forward direction, the torque tube prevents the differential from rotating during acceleration. It achieves this by coupling the differential housing to the transmission housing, effectively transferring propelling force to the car frame. This mechanism allows for smooth acceleration and braking, enhancing overall driving performance and control.

Components and Construction of Torque Tubes

The torque tube comprises essential components contributing to the vehicle’s drivetrain system. Its core is the hollow tube housing the rotating driveshaft, with a universal joint inside allowing relative motion. At one end, a ball and socket joint called a torque ball provides flexibility between the axle and transmission. Some designs incorporate radius or panhard rods for additional stability. Together, these components ensure proper transmission of traction forces and support the vehicle’s suspension.

The term “torque tube” refers to a component in a vehicle’s drivetrain system that addresses the issue of transmitting traction forces from the wheels to the car frame. Unlike the name suggests, it’s not about the torque of the driveshaft but rather the torque applied by the wheels. The torque tube solves the issue of the differential’s inability to rotate during braking and acceleration. It accomplishes this by coupling the differential housing to the transmission housing, transferring the propelling force to the car frame. Additionally, the torque tube houses the rotating driveshaft and utilizes a ball and socket joint, known as a torque ball, to allow relative motion between the axle and transmission. This design ensures a rigid rear end and good alignment under various driving conditions, albeit with the drawback of increased unsprung weight and potential rear-end movement during certain maneuvers.

Function and Purpose of Torque Tubes

The torque tube is crucial in a vehicle’s drivetrain by transmitting traction forces from the wheels to the car frame. Despite its name, it’s not about the driveshaft’s torque but rather the torque the wheels apply. Its primary purpose is to prevent the differential from rotating during acceleration and braking. Attaching the differential housing to the transmission housing delivers propulsive power to the automobile frame, guaranteeing stability and alignment during driving maneuvers.

Types of Vehicles that Commonly Use Torque Tubes

Torque tubes are prevalent in many vehicles, from traditional rear-wheel-drive cars to heavy-duty trucks and SUVs. They transfer power and traction from regular cars to off-road and high-performance vehicles, particularly on difficult terrain. Furthermore, vintage and classic cars often feature torque tube configurations, showcasing their enduring design and reliability. These components are integral to vehicles that prioritize durability, robustness, and consistent performance across various driving conditions.

Advantages and Disadvantages of Torque Tube Systems

Advantages:

Torque tube systems offer several advantages in vehicle design and performance. First, they provide a rigid connection between the rear axle and transmission, ensuring consistent alignment and stability, especially during high-speed maneuvers. Second, torque tubes lessen vibrations and noise from the powertrain, making driving more peaceful and comfortable.

Furthermore, their compact design contributes to weight reduction and improved fuel efficiency. Overall, torque tube systems enhance vehicle handling, comfort, and efficiency, making them a preferred choice in many automotive applications.

Disadvantages:

Despite their many advantages, torque tube systems also have some drawbacks. Their intricacy is one of their primary drawbacks since it may make upkeep and repairs more difficult and expensive. Furthermore, torque tube systems are often heavier than alternative powertrain arrangements, increasing the vehicle’s weight and decreasing fuel economy.

Moreover, the rigid connection between the transmission and rear axle limits suspension articulation, potentially compromising off-road performance. While torque tube systems offer several benefits, they also have certain drawbacks that should be considered when considering vehicle design and usage.

Maintenance and Care for Torque Tubes

Torque tubes must be tended to and maintained to provide the longest possible lifespan and optimal performance from the vehicle’s powertrain system. Regular inspections, lubrication, and cleaning are key maintenance practices to prevent wear and corrosion. Additionally, monitoring for signs of damage or excessive wear, such as leaks or unusual noises, is essential for the early identification of such problems.

By following a regular maintenance plan and quickly resolving any issues, vehicle owners can prolong the lifespan of torque tubes and avoid costly repairs down the line.

Common issues or Problems with Torque Tubes

Torque tubes might develop issues or problems due to common difficulties, wear, strain, poor maintenance, or manufacturing flaws. One common issue is leaks or seal failures, which lead to lubricant loss and potential damage to internal components.

Additionally, corrosion or rusting of the torque tube can occur, compromising its structural integrity and performance. Other issues may include misalignment, excessive vibration, or bearing failure, affecting drivetrain operation and overall vehicle performance. Regular inspection and timely maintenance are essential for addressing these issues and ensuring the torque tube’s reliability.

Future Trends and Advancements in Torque Tube Technology

As automotive technology continues to evolve, torque tube systems are also expected to undergo significant advancements. Future trends include developing lighter and more durable materials for torque tubes, which will enhance fuel efficiency and performance.

Additionally, advancements in manufacturing processes and design optimization techniques could lead to torque tubes with improved strength-to-weight ratios. Predictive maintenance algorithms and smart sensor integration may also increase, enabling proactive maintenance plans and early problem identification. These advancements further enhance the reliability, efficiency, and performance of torque tube systems in modern vehicles.

Conclusion

The torque tube makes effective power transfer and reduced drivetrain vibrations possible, which is essential in transferring rotational force from the engine to the wheels. Despite its name, it’s not about the torque of the driveshaft but rather the torque applied by the wheels. While torque tube systems offer advantages like stability and reduced drivetrain noise, they have drawbacks like complexity and increased vehicle weight. Proper maintenance is crucial to prevent common issues like leaks or corrosion. As automotive technology evolves, future trends bring lighter materials and smart sensors to enhance torque tube performance and reliability.

FAQ

What is the meaning of torque tubes?

A torque tube links the stationary components at each end of the driveshaft, such as the rear axle and transmission. The driveshaft rotates within the tube, transmitting rotational torque.

What does a torque tube do?

The torque tube stabilizes the rear end, preventing axle wrap during acceleration and braking.

What is a turbine tube?

Tubular turbines are axial turbines with axial or diagonal inflow to guide vanes, typically mounted on horizontal or inclined shafts.

Why is torque important?

Torque enables rapid acceleration in your car, while horsepower influences its maximum speed. Electric vehicles (EVs) often boast higher torque than gasoline-powered cars, resulting in faster acceleration.

What are the two types of drive shafts?

- One-piece drive shaft.

- Two-piece drive shaft.

- Slip-in-tube drive shaft.